Do you know what artificial turf is made of? You probably don’t if you’ve never seen or played on it. Synthetic turf, often known as artificial turf, is a surface consisting of synthetic fibers intended to resemble natural grass in appearance and feel. It is primarily used in arenas for sports played on the grass. While there are different types of artificial turf available, they all have one common goal: To provide a safe and comfortable surface for athletes and spectators. In addition, it is effortless to maintain, and it does not need watering or trimming. So, what goes into making this man-made material? Keep reading to find out!

History of Artificial Turf

The tufting process was invented in the early 1950s. Many needles were inserted into filaments of fiber into fabric backing. The procedure was mainly used in making

residential carpets. The Ford foundation asked the science industry to develop a synthetic playing surface for urban space. This gave the urban children a round surface with a better play quality field. The first successful installation of a playing surface called Chemgrass was done in1964 at Moses Brown School in Rhodes Island. The artificial turf was then used in 1966 when installed in the Houston Astrodome, a world-first domed indoor multipurpose sports stadium. This was after the stadium’s natural grass failed to grow during the stadium’s inaugural season in 1965. They were forced to install the artificial turf since the stadium condition was terrible. The artificial turf market expanded with other new manufacturers entering the field.

Pros of Artificial Turf

Artificial turf has many benefits for the consumer, which include:

1). It Saves Money and Time.

Natural grass requires a lot of water per square foot annually. However, artificial turf does not require water, saving the monthly water bills.

Natural grass fields will turn to muddy in heavy rain. If you play on the field, you end up destroying the grass. However, with artificial turf, players will leave a perfect field behind whether it rains or not.

2). Artificial turf fields are versatile and can endure heavy uses, unlike natural grass.

Natural grass will need some time to recover before the next game is played on it since it can only withstand about 100 events hours of use. However, the artificial turf fields can withstand approximately 500 events hours.

3). Artificial Turf is long-lasting.

Artificial turf can last for more than twenty years. Also, once installed, it remains green, and it can never dry out, be overgrown or develop brown spots like natural grass.

4). Artificial turf is easy to maintain

Since artificial grass doesn’t grow, it does not require maintenance. One does not require fertilizers, pest control products, and any lawn care equipment.

5). It is easy on the skin

There is minimum friction since artificial turf technology has developed a polypropylene surface. The surface minimizes the risk of friction between the skin and the surface.

Cons of Artificial Turf

The artificial turf also has the following limitations.

1). There is reduced flexibility.

The natural grass fields are painted on and can be changed according to the game. However, changing colors with artificial turf is harder, more expensive, and time-consuming.

2). It retains heat.

The fibers in artificial turf are made of nylon or polypropylene that are heat absorbent. The field could be too hot to plan on sunny days. The field needs to be watered before being played on to avoid this.

Raw Materials for Artificial Turf.

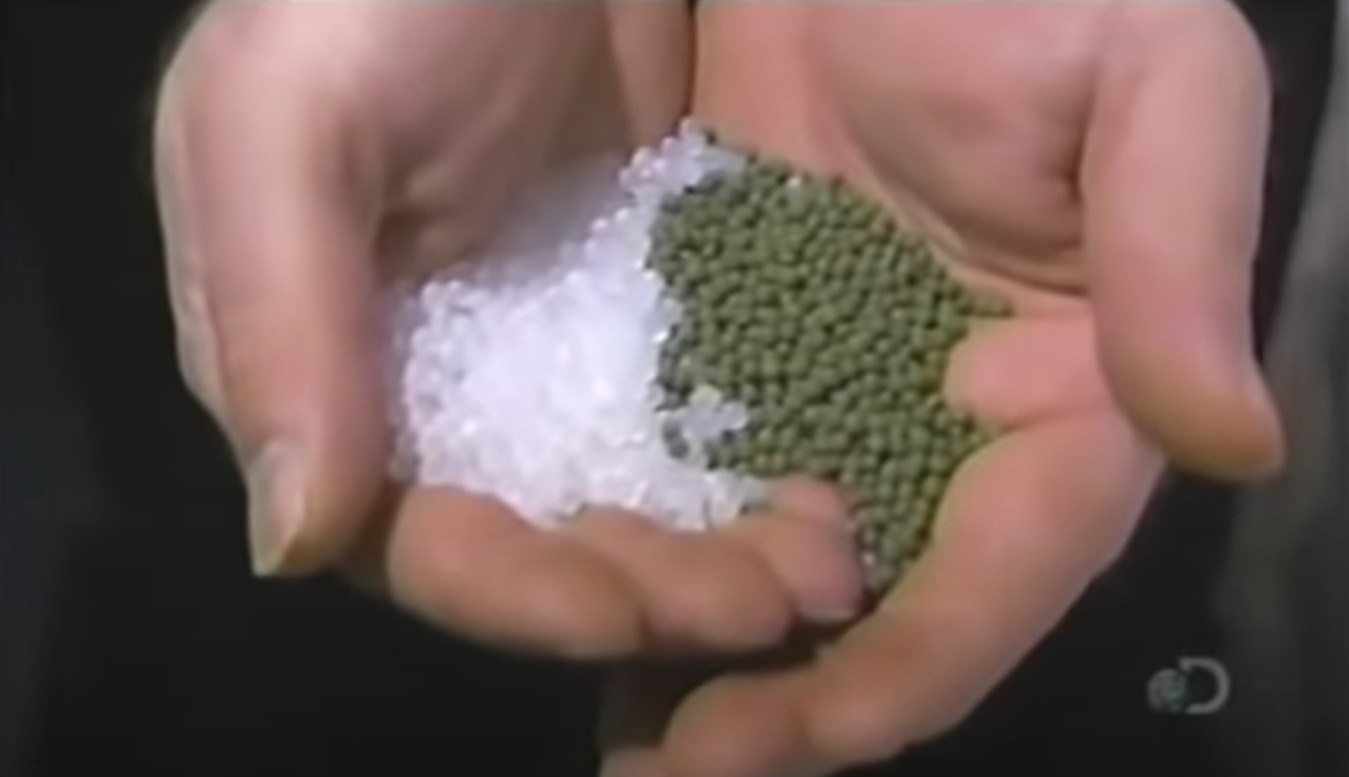

The quality of the raw materials is vital to the performance of the turf system. All the materials used as carpet backing have been used for artificial turf backing, from jute to plastic to polyester. High-quality artificial turf uses polyester tire cord for backing. The fiber that makes up the blades of grass is made of nylon and can be manufactured in many ways. The blades, which are nylon, can be produced in thin sheets cut into strips to produce fibers with a round cross-section. The product results in blades that feel and act like biological grass.

On the other hand, the cushioning system is formed of rubber compounds, and the rubber foundation is made of rubber tires. The thread used to sew pads together and the fabric panels have the basis of strength, color maintenance, and durability as the rest of the system.

How Artificial Turf is Made

The manufacturing process of artificial turf is the same as that of carpets. The steps include:

1. Blending the proprietary ingredients. Chemicals and dyes are added to give the turf its traditional green color and protect it from the sun’s ultraviolet rays.

2. After blending, the batch is fed into a large steel mixer, and it is mixed until it becomes a thick, soft consistency.

3. The thick liquid is then fed into an extruder and exits in the long, thin strand of material.

4. The strands are then placed on a machine that cleans and fixes spun into loose rope. The ropes are then pulled, straightened, and woven into yarn. Finally, the nylon yarn is wound onto large spools.

5. The yarn is heated to set the twisted shape.

6. The yarn is then moved to a tufting machine. The nylon yarn is put on a bar with a reel behind the tufting machine, then taken through a tube leading to the tufting needle, which pierces the main backing of the turf and then pushes the yarn into the loop. A looper grabs and releases the nylon loop while the needle pulls back. Several hundred needles carry out the process and several hundred rows of stitches per minute. The nylon yarn now becomes the artificial turf.

7. The artificial turf is rolled under a dispenser that spreads a latex coating onto the turf’s underside.

8. The artificial turf is placed under heat to cure the latex.

9. The turf is taken through a machine that clips off any tufts that rise above its uniform surface.

10. Lastly, the turf is rolled and packaged. The rollers are then shipped to the wholesalers.

While installing the artificial turf, the base should either be concrete or compacted soil which a bulldozer must level and then smoothed by a steam roller. A drainage system should be installed for outdoor applications since the underlying surface can absorb little rainwater.

Quality Control of Artificial Turf

Since artificial turf is mainly used for sports, new products must undergo several tests as they are being produced. First, the backing fabric should be tested for strength. Also, the force it takes to separate the individual tufts is measured. The test to how resistant the turf is to abrasion. There is a test that measures the turf system’s shock absorbency.

These quality checks are performed during the manufacturing process, as the American Society for Testing and Materials recommended.

The Future of Artificial Turf

The engineering of both artificial and biological turf systems is constantly changing with new advancements that serve both economic and environmental needs. There is a recent development has been a hybrid of filled turf and natural grass. Installing the artificial turf is filled with soil and not sand or rubber. The grass seed is planted in the soil, nurtured, and grown to the height above artificial turf. The result combines natural turf’s feel, look, and comfort with resistance to tearing artificial turf. Unfortunately, it is required to maintain both systems and is unsuitable for indoor applications.

Final Take Away

As described above, artificial turf has pros, including its versatility and long-lasting qualities, and it has a few cons. Used mainly in sports arenas’ artificial turf is also gaining popularity in backyards and office spaces. Though there is a place for natural grass,

artificial turf is here to stay due to its excellent benefits.

Recent Comments